How to Laser Cut

How do I Laser Cut or Engrave?

What equipment is available? How much does it cost?

What is your policy on personal or commercial projects?

How to Laser Cut

More information on laser cutting can be found in our Laser Cutting Workshop – if you have questions email us at dscommons@uvic.ca.

To submit a laser cutting request, go to https://webapp.library.uvic.ca/3dprint/.

Step 1 – Design or Download a .svg or .pdf drawing

- Create your own design using Inkscape, Adobe Illustrator, or similar softw

are.

are. - Download a laser cutting design.

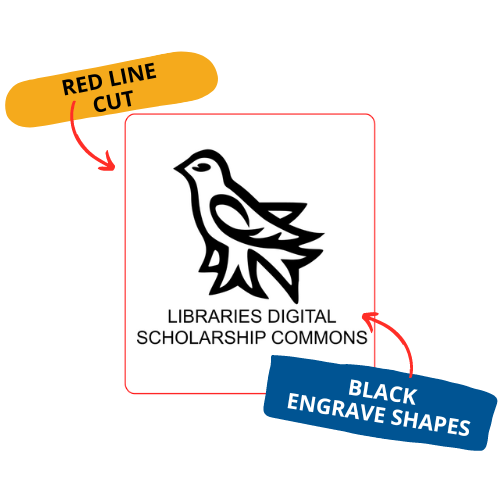

- Make sure the design uses different colours to indicate cutting and engraving, if your design has both. As a general rule of thumb, Red=cut, Black=engrave.

Step 2 – Prepare your file to be laser cut

- Open the file in Adobe Illustrator or Inkscape (or a similar software) to check your design and organize all parts of your design.

- The maximum possible size is 59cm x 29cm; larger laser cuts will need to be divided into multiple pieces (limited templates for size are available here)

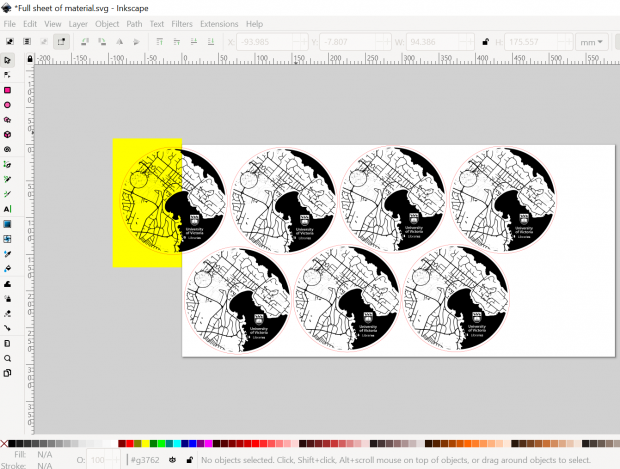

If you need multiple copies of a single pattern, copy and paste your design accordingly in your .svg or .pdf file. Each design element must fit

within the dimensions of one full or half sheet of material. Any design element outside the sheet will not be laser-engraved or cut (in the image below, the portion in yellow is outside the material sheet).

If you want multiple copies of one full sheet, please indicate this in the additional comments. The file will be sent to the laser cutter twice, with no modifications.

Step 3 – Get your design cut!

- Upload your *.svg or *.pdf to the web app here.

- Choose your specifications – indicate which colors are for cutting or engraving, the material type, and any other special settings.

- DSC staff will take a look at the project and email you a price.

- Follow the instructions sent via email to pay for your order.

Step 4 – Pick up at the library

We will send you an email once your laser cut job is ready for pickup. It will be available from the “Ask Us” desk.

How much does it cost?

Laser cuts cost $0.33 per minute of engraving and cutting time, with an additional fee based on material and width. See the table below for material fee.

You can buy materials that are pre-approved to be used on our machine, at this time we only accept low-odor materials (acrylic is not suitable for our current setup). Laserable materials are sold in full or half sheets (we buy in bulk to provide you with the lowest price possible!). Please ensure that your design fits the space provided (limited templates for size are available here). If you prefer to bring in your own material, please indicate this when submitting your online form. All materials that are not purchased from the DSC need to be reviewed by staff prior to a job taking place and we reserve the right to refuse any material that could put at risk our staff or equipment.

| Material | Dimensions | Full sheet | Half sheet |

| Plywood 3mm | 29cmx59cm | $6.50 | $3.25 |

| Plywood 6mm | 29cmx59cm | $9.60 | $4,80 |

| MDF 3mm | 29cmx59cm | $6.90 | $3.45 |

| MDF 6mm | 29cmx59cm | $9.40 | $4.70 |

| Hardwoods and other materials available upon request. | |||

Step 3 – Get your design cut!

Laser engraving and cutting is a quick process, most projects take between 5 minutes to an hour to complete. However, turnaround varies depending on the time of the semester and staff availability. During end of term when projects are due, it may take a couple of weeks or more. If it is a slow time, turnaround is less than a week.

- Plywood: our cheapest material, in 3mm and 6mm thicknesses

- MDF Wood (Medium-Density Fibreboard): slightly denser and darker than plywood, available in 3mm and 6mm thicknesses

- Higher-quality wood: contact us for special requests.

- We can also engrave metals such as anodized aluminum, but you must provide the material yourself – email us at dscommons@uvic.ca for more information or to book an appointment.

- At this time, we do not work with acrylic.

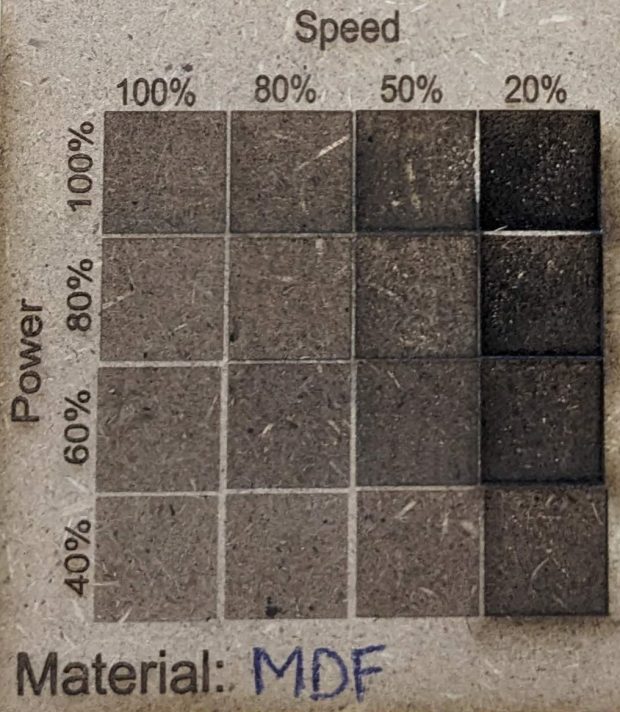

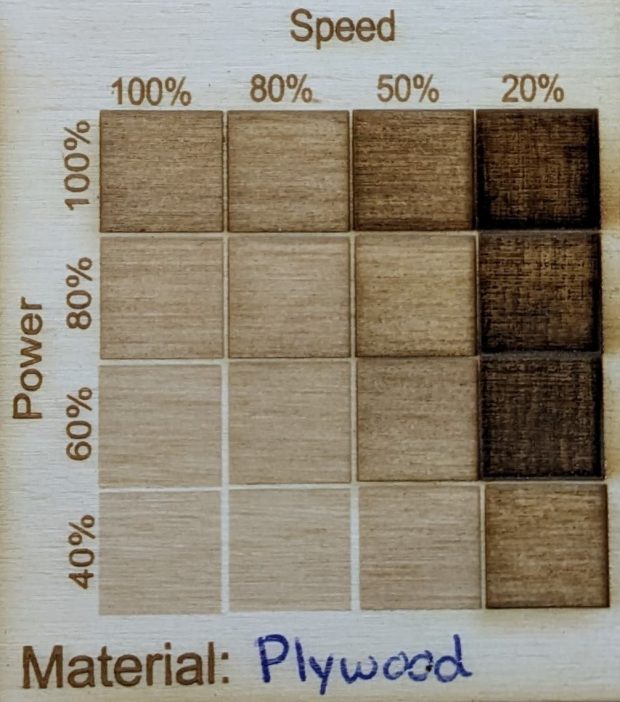

What settings do I use?

- Settings will vary depending on the type of material selected. If no special settings are requested, we will use the recommended settings for the material.

- Specify if you want to cut or engrave your design. If the file has both cutting and engraving, specify which colour is which. (e.g red lines are cut, black lines are engraved)

- % Power: higher power settings will result in a deeper or darker engraving. Very high power will cut through the material instead of engraving.

- Speed: unlike with power, increasing the speed will make the engraving lighter. Very slow speed might cut through the material instead of engraving. Requesting slower speeds will result in a longer laser job and could therefore increase cost.

- Passes: similar to power, increasing the number of passes will make an engraving darker. For fragile thin materials like paper, it may be better to have multiple passes at low power instead of a single high powered pass. Requesting multiple passes will result in a longer laser job and could therefore increase cost.

- Material swatches for our most common materials are available below and in-person in the DSC. Please note that since wood is an organic material, each piece will be slightly different and that results may vary.

We use a Trotec Speedy 100 laser; any special settings can be requested in the comments box when submitting a request.

If you have questions about the best settings to use for your project, please email us at dscommons@uvic.ca to book a one-on-one appointment, we’re happy to help!

What is your policy on personal or commercial projects?

Personal jobs are permitted and encouraged but are given the lowest priority to try to ensure that academic jobs, which may be time-sensitive, can be done before assignment deadlines.

Last-minute submissions, including academic projects, might not be able to be completed in time due to limitations in the capacity of our equipment and staff. Depending on the scope of your project, providing as much lead time as possible is required.

All projects submitted through the DSC should be for academic, personal use, and prototyping purposes. Commercial projects are not permitted. If you have questions regarding the eligibility of your project, please contact us at dscommons@uvic.ca to talk to our staff.

Helpful Links:

- Workshop: Design for Laser Cutting

- Thingiverse https://www.thingiverse.com/

- Instructables laser cutting projects

Please email us at dscommons@uvic.ca or book an appointment with us if you have any questions. Happy lasering!