UVic researcher, Dr. Katherine Elvira, learned about drug discovery and microfluidics in the final year of an integrated undergraduate Master’s degree. She became fascinated by the topic. This fascination fueled her desire to run her own lab centered around these topics. She recently filed a provisional patent (application number: 62/968,616) titled “Microfluidic Platforms for Drug Discovery.” This technology shows great promise in providing a microfluidic platform to test pharmaceuticals or cosmetics without animal models. In addition, it will allow for better prediction of the pharmacokinetic pathway in humans in a high throughput capacity. Read the interview below to learn more about Katherine’s journey to lead a research group investigating microfluidics for healthcare and drug discovery and her provisional patent.

- How long have you been studying microfluidic techniques? When did you become interested in developing microfluidic devices for the construction of materials such as tissues or organs for preclinical or biomedical applications of pharmaceutical products?

During the final year of my degree I took a course that was taught by a drug discovery company that described how they developed new drugs, and analyzed the way a drug could act with the human body. I also took an upper level course on microfluidics that I found really interesting. I ended up doing my PhD on microfluidics for automated chemical reactions, but I also did some work on artificial cells. My post-doc really broadened my experience, allowing me to get a lot of experience with different types of microfluidic technologies. What I am really interested in is building artificial life on a chip, and that is what I am now doing now, here at UVic.

- In one of your publications it is cited that 30% of drug candidates fail upon testing on animals because they can’t predict drug pharmacokinetics. What is the road block researchers are finding when trying to discover the pharmacokinetic pathway in humans?

You can’t test drugs on humans until the end of the drug development process and animals aren’t humans! This is the simplest way of thinking about it. There are decades of experience in this area and drug discovery researchers are very good at making correlations, but it just isn’t good enough. We are still looking for better ways. For example, there are people developing computational models, or organs on a chip. There are lots of different takes on the same problem. When you put a drug in human and it doesn’t work, it’s too late, billions of dollars have already been spent. The biggest road block is that we don’t know how a drug will act until the drug, in question, is taken to clinical trails and tested on humans. There needs to be better middle steps for drug testing.

- How does your invention address the road blocks found in current state-of-the art methods for testing pharmaceutical drugs?

We just don’t have a strong enough understanding of the interactions between molecules and humans. Even a cell is very complex. Drugs have to pass through the cell membrane, and there are loads of things inside the cell and on the cell membrane that affect this process. When you do cell-based assays it is hard to narrow down how a drug candidate interacts with cells because of this complexity. What I was thinking when I designed this technology was: what if we designed the cell from the bottom up, starting with a cell membrane so you can make it bespoke? We needed better in-vitro tests. When we do in-vitro tests we really want to predict what happens in-vivo. These were the problems I was seeing, and the problem that I am addressing through the development of the microfluidic platform for drug discovery patent.

- Are you able to construct a variety of different tissues to use in preclinical or pharmaceutical applications?

Yes. We are looking at complex intestinal models, and we are also starting to work on Alzheimer’s disease models. We want to optimize this technology for a variety of different tissues and diseases.

5. Can you describe how your technology is a novel platform for high-throughput screening of pharmaceutical molecules and/or cosmetic products?

All microfluidic technologies are effectively high-throughput. The way that we built this three-droplet model of artificial cells allows us to parallelize it. A comparable system is Parallel Artificial Membrane Permeability Assay (PAMPA).  That is the typical 96 well plate, high-throughput model. We are making our technology a lot more biometric but still are able to do it in high-throughput. This technology shows promise to be able to run 900 assays per hour.

That is the typical 96 well plate, high-throughput model. We are making our technology a lot more biometric but still are able to do it in high-throughput. This technology shows promise to be able to run 900 assays per hour.

- How simple is this technology to use and what are the cost benefits?

Once it is up and running it is really easy to use. We are still optimizing the platform. Ideally, someone would be able to follow simple steps that would be geared to their drug of choice for an easy testing methodology.

- What are your next steps for this technology?

We want to miniaturize the detection system. Not all drugs fluoresce. Within the next year or so we want to try and discover how to detect drugs that don’t fluoresce within this platform. We would love to develop this in the lab and then somehow miniaturize it.

In the future, we would also want to integrate our current platform with detection instruments that pharmaceutical companies already have, such as mass spectrometers.

What keeps you inspired?

I am always curious. Having a research lab is like having a big problem, and having the ability to try different ideas to solve the problem. I also like to think that we will be able to discover something that could make the world better.

- How do you relax from a long day in the lab or grant writing?

I like to do yoga and snowboard. Hanging out with friends is relaxing to me, human interaction keeps me going! I also really like to travel.

For more information on this technology or to inquire about collaboration please contact Research Partnerships (RPKM) here

Photo Credit: UVic Photo Services

Written by Liz Bueckert.

industry-academic partnership is contacting an ILO with a new idea. They can connect you with relevant researchers to develop the innovation or highlight technologies ready for commercialization that offers a solution to common problems within your industry. Partnerships can begin early in the research phase, part way through development when a technology needs to be optimized, or when the technology is ready for licensing.

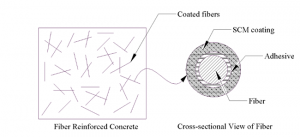

industry-academic partnership is contacting an ILO with a new idea. They can connect you with relevant researchers to develop the innovation or highlight technologies ready for commercialization that offers a solution to common problems within your industry. Partnerships can begin early in the research phase, part way through development when a technology needs to be optimized, or when the technology is ready for licensing. [about 8% of the total global carbon dioxide]. There are many other SCMs some of which are very expensive. There is also silicafume which is an exceptional material that has the ability to remove lime. Limestone is put into the mixture to make concrete, but the limestone turns to lime and actually makes concrete less durable. When you add silicafume to the concrete it reacts with the lime and reduce the amount of lime in the concrete. What is great is the reaction between lime and silica produce a really amazing product that reduces deterioration.

[about 8% of the total global carbon dioxide]. There are many other SCMs some of which are very expensive. There is also silicafume which is an exceptional material that has the ability to remove lime. Limestone is put into the mixture to make concrete, but the limestone turns to lime and actually makes concrete less durable. When you add silicafume to the concrete it reacts with the lime and reduce the amount of lime in the concrete. What is great is the reaction between lime and silica produce a really amazing product that reduces deterioration. around the clock, to churn the headbands out as quickly as possible.

around the clock, to churn the headbands out as quickly as possible. are packaged into a transparent plastic bag along with the elastic band. In addition, to disinfect the kit further, the kits are each placed into an Ultraviolet sterilization cabinet for 15 minutes.

are packaged into a transparent plastic bag along with the elastic band. In addition, to disinfect the kit further, the kits are each placed into an Ultraviolet sterilization cabinet for 15 minutes.