As a teenager, UVic Professor, Rishi Gupta spent his weekends at construction sites with his father, who had a PhD in concrete technology. These weekends allowed Dr. Gupta to learn the intricacies behind creating concrete from cement, learn the impact production has on the environment, and how great ideas can become tangible, if you just put pen to paper. Dr. Gupta’s passion for the science of concrete was ignited at an early age, this passion continues to grow, and his innovations are making great strides towards stronger, cleaner infrastructure. Learn more about Dr. Gupta and his “Surface Treatment for Concrete Reinforcement” for which he has been granted a National US patent (IP No. 9908813), and is available for licensing.

- Your research space is the Facility for Innovative Materials and Infrastructure Management (FIMIM), given your area of research were you always looking for an opportunity to improve the cement to concrete processes or was this a happy accident?

The idea of improving the interface of enforcement is a long standing issue. Concrete is the most used material world-wide and has been for a very long time. A perfect marriage took between concrete and steel to produce reinforced concrete that is now a very popular construction technique. Concrete is brittle and steel ductile, but steel will cause corrosion. A big portion of money these days is spent on rehabilitation of infrastructure constructed using reinforced concrete.

It was always on my mind that the use of steel as a reinforcement of concrete continues to be an issue. There is epoxy coated rebar but these are synthetic coatings and concrete has a cementitious binder, thus creating issues. I wanted to improve the bonding of reinforcement by improving the interface between the rebar and concrete. I thought, let’s replace the coating. Rather than improving the entire matrix why not put the stuff where it needs to be in the [exact area of] reinforcement, on the surface.

- What is the current problem with the production and life cycle of cement?

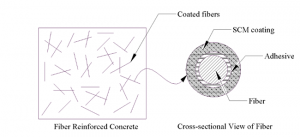

Concrete on its own can last forever. It is like an artificial stone. The problem comes when you add steel, or synthetics or glass, concrete treats all of these materials as foreign and the interface becomes weak. This interface is called the interfacial transition zones (ITZ). That’s what this innovation is focused on. The ITZ is not visible to the naked eye. This is the analogy I like to use for what is happening at the ITZ:

If you have a bunch of soccer balls in a net you can pack them up pretty closely. If you take those soccer balls and push them up against a wall they don’t pack as tightly, there are big gaps between the balls and the wall. The wall is considered the reinforcement, such as rebar, and the balls are the small cement particles. The less closely the balls pack to the wall the more pores there are. This creates many large pores right at the interface and bonding is greatly reduced. The second problem with increased porosity is that harmful elements like salt, sulfates and carbon dioxide get closer to the reinforcement faster causing weakness and increased deterioration. The environmental effect can further deteriorate the already weak ITZ. The service life of the entire structure ends up being much shorter than anticipated due to these factors.

- How does your patented, concrete surface treatment solve this problem?

There are well known substances that we call supplementary cementitious material (SCM). An example of SCM is fly-ash. Fly-ash is produced when coal is burned in thermal power plants. When you add this waste material to concrete it makes concrete stronger. So, it was a no-brainer to add a SCM to concrete, environmental waste is removed from the environment, a home is found for the waste, and in turn, the amount of cement used is reduced. This makes a positive global impact because the production of cement emits a lot of carbon dioxide  [about 8% of the total global carbon dioxide]. There are many other SCMs some of which are very expensive. There is also silicafume which is an exceptional material that has the ability to remove lime. Limestone is put into the mixture to make concrete, but the limestone turns to lime and actually makes concrete less durable. When you add silicafume to the concrete it reacts with the lime and reduce the amount of lime in the concrete. What is great is the reaction between lime and silica produce a really amazing product that reduces deterioration.

[about 8% of the total global carbon dioxide]. There are many other SCMs some of which are very expensive. There is also silicafume which is an exceptional material that has the ability to remove lime. Limestone is put into the mixture to make concrete, but the limestone turns to lime and actually makes concrete less durable. When you add silicafume to the concrete it reacts with the lime and reduce the amount of lime in the concrete. What is great is the reaction between lime and silica produce a really amazing product that reduces deterioration.

Let’s come back to the analogy of soccer balls – if I want to improve the packing of the soccer balls I would add a SCM to concrete. If the need is to improve the ITZ, why not just add SCM into the ITZ. In other words, put it on the specific parts of the wall rather than the all over the room (or throughout the net with the balls). This would allow the reinforcement to be the carrier of SCM and when the lime is produced in the ITZ, the SCM reacts with the lime and yields calcium silicate hydrate gels, these are good gels. SCM + free lime = good gel to improve mechanical strength and makes the IT zone less porous, improving overall strength and service life.

- With a weakened ITZ – how long is the expected service life?

In Civil Engineering if we talk about bridges reinforced with concrete, they typically have a design life of 75 years, but what we have actually found is that bridges in North America were only lasting 40 years. This brings up the question of what is going wrong. The infrastructure owner paid for a service life of 75 years, so what happened to those additional 35 years? On closer inspection, premature deterioration is found, and a wide spread problem of corrosion. In cooler climates ice and salt cause rust and additional corrosion. This is where the service life has been lost. Just concrete it self would have a service life of 100+ years because stone lasts forever, but the tensile strength of concrete is only 10% that of steel. The tensile forces of steel and the compression forces of concrete equal the best combination for construction.

- How does the addition of a SCM improve the service of concrete?

We know there will be improvement in long term durability because there are changes in the microstructure of the ITZ by eliminating lime, reducing porosity, reducing corrosion and improving durability. The whole industry has done a ton of research on concrete corrosion. We know this will greatly reduce corrosion rates.

My innovation will increases the service life of concrete, but also reduces the total amount of materials required for repairs or replacement structures. My new reinforcement is a higher end version that performs better in bond strength and lasts longer when compared to what is currently available. The amount of reinforcement is actually reduced. At this moment, it is better to assume that the amount of reinforcement remains the same but this technology adds additional benefits.

- How do you think this will positively impact a greener use of concrete?

Simply extending the service life of concrete structures will have a positive impact on the environment. If the addition of the SCM reinforcement allows the structure to last for the full design life (75 years) we are not replacing infrastructure as often, reducing carbon dioxide emissions and reducing the use of replacement materials. The front-end aspect is that most of the SCM are industrial waste materials such as silica fumes and fly ash. Really, any material with pozzolanic capacity could be used as the coating. If you can identify a SCM it can typically be used as a reinforcement coating material, and this allows for a cleaner, greener way to reinforce concrete and increase the service life.

- How do you stay inspired and spark creativity to continually generate new ideas?

My introduction to engineering happened when I was a teenager, and my father happened to have a PhD in concrete technology. I would spend my weekends hanging out on construction sites. My father would always say, “civil engineering is amazing because you have something sketched up on paper and then you get to see it come to life.” This had a life changing effect on me, and it continues to keep me inspired today. I am always thinking of new ideas. It also helps that I am also surrounded by exceptional students that help keep the creative spark alive in me.

- How do you clear your head after a long week in the lab?

I have a 5 year old at home and 75+ year old at home. I feel blessed to come home and unwind with my family. The kind of work that I am in is non-stop, my mind is continually going, but when I come back home to be with my family I get to detox from all that is happening in my professional life. I also really enjoy being in the moment with my 5 year old by bike riding and swimming.

To read more on this technology head over to the Research Partnerships Technology Portfolio here

Written by Liz Bueckert.