A trail hopping, corner crushing caboose! Designed as the perfect bike for a riding a local gem, Mt. Tzouhalem!

Estimated Completion: January 2026

Full Project Release Coming Soon!

A Major Milestone

The Doug was our proof of concept. Out next mission was to create a bike that would handle more stress and load, more gnar, and with much less room for error. Refinement and improvement was the name of the game, and we were ready to embark on our first aggressive mountain bike!

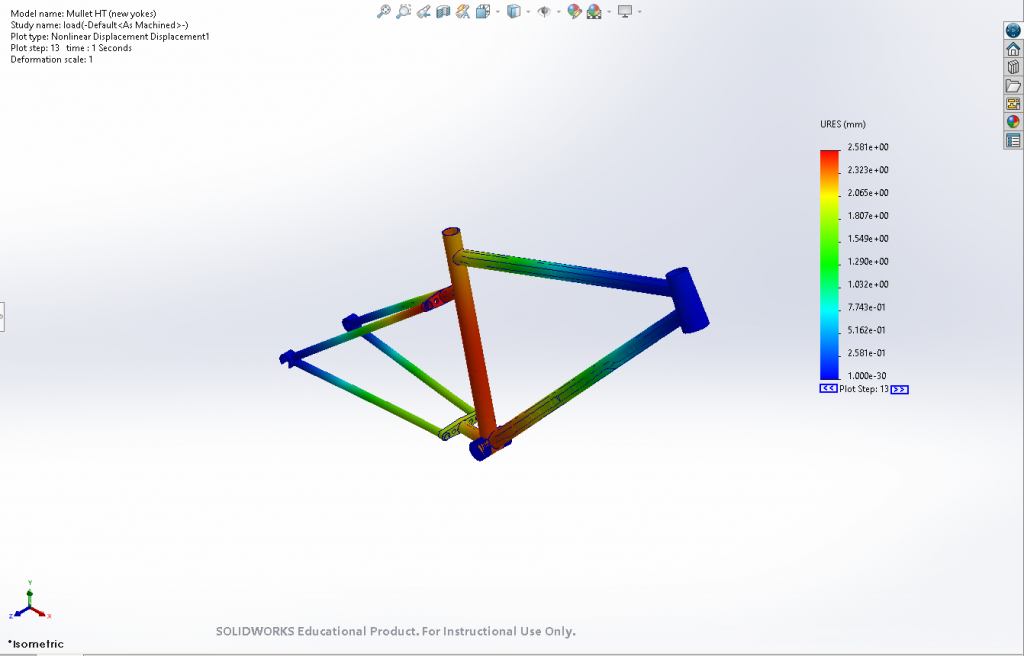

Design & Simulations

Created in SolidWorks from industry standard tubes, we designed a slack 150mm trail configuration, with custom BFS axel dropouts and tapered headtube.

To meet our FOS (Factor of Safety), we simulated maximum load-stress and FEA’s to ensure rider safety with plenty of room for error.

Procurement

Our original concept avoided any bent or angled tubes to match our MFG capability, and focus on a yoke based design.

We partnered with VR3 Engineering to expand our capability to machine bent & mitered tubes for our bikes! This opportunity allowed us to avoid tire clearance yokes, and create a much stronger and lighter rear triangle. Our team assembled the BOM, drawings, and procurement forms to cut out our next bike!

Manufacturing & Machining

As we proceed with as much in house manufacturing as possible, we created a local initiative through the UVic machine shop, allowing us to make critical frame, jig, and component parts!

This milestone not only brought our manufacturing closer to home to streamline our process, but it allowed BDAM members to get hands on experience turning, milling, and fabricating our precious steel and alloys!

Fabrication

With our new and improved welding Jig complete, we upgraded our fabrication gear to a full TIG & MIG system, moving away from brazing.

As with any new step, training is key! BDAM members got an exclusive opportunity through Camosun College to attend their metal fabrication workshops. Our fabrication process was carefully engineered to minimize heat distortion, avoid compounding frame deformation, and ensure adequate and consistent weld strength.

Utilizing 3D printed snap-on angle guides, no measuring was needed when it was time to melt. Created from out SolidWorks models for our frame and Jig, using geometry “molds” was a key upgrade to ensure accurate angles, location, and mitre rotation.