A Little Backstory

For our first bike, we had one goal. Create a new breed of bicycle, and prove our concept as a club and team. Doug was designed to be the perfect set of wheels for Victoria B.C. A bike that could rip down bike lanes with its fast and light design, while still being capable of tackling some gravel when times get choppy. Named after a staple of Victoria, Mount Doug.

In the Beginning

Our first challenge was answering the age-old question. How does one build a bicycle? After hours of researching mitering techniques, welding, jig strategies, sourcing materials, touring bike factories, and brainstorming assembly procedures, we created our plan.

The next question was a little easier to answer. What kind of bike should we build? With some help and inspiration from a donated bike, we put our pens to the paper, and cursers to the CAD models to begin dimensioning and experimenting with frame designs. After a collective consensus on geometry and shape, we had our bike on paper.

Picking the Geometry

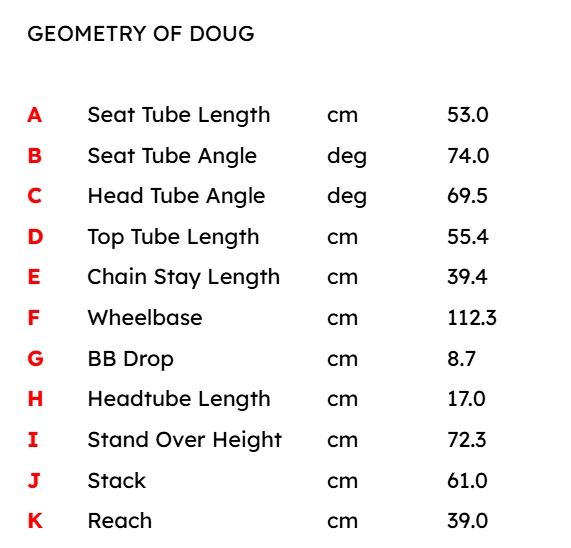

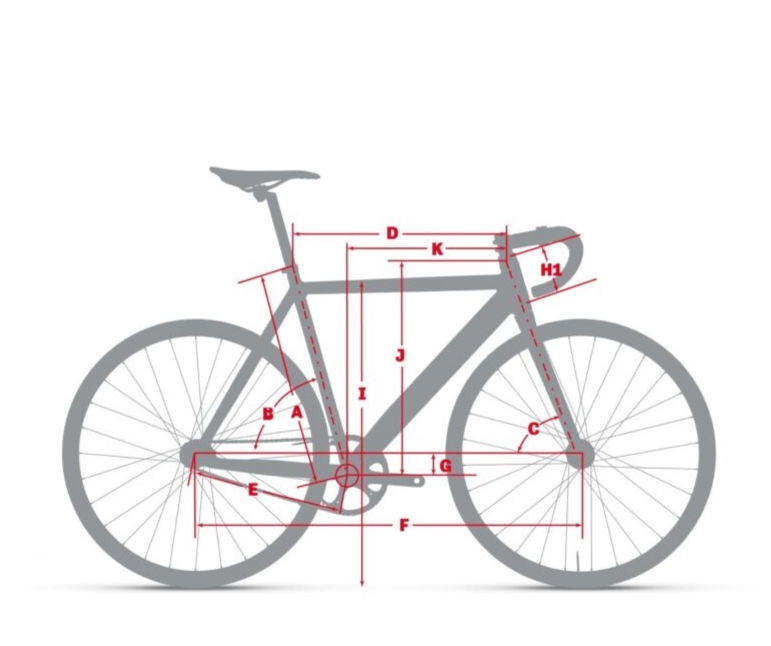

This was where the magic happened. What kind of bike did we want to create? The world was our oyster! With dozens of sources of inspiration, our team settled a style of frame perfect for ripping around campus. Utilizing modern standards with steep head tubes with slack seat tubes, we created a frame in between a gravel and touring bike. Tolerancing these angles depended on where the critical dimensions were, notably the head, seat, and bottom bracket drop.

An Interesting Challenge

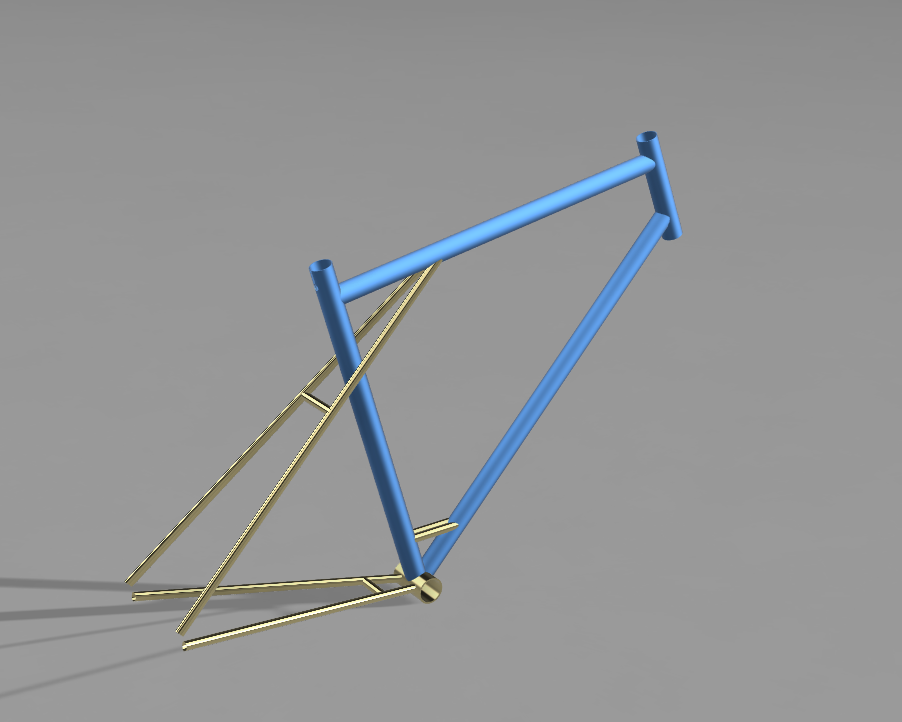

As a club, we strive for creative and efficient innovation of our bikes. One of our biggest goals (and biggest obstacle) was designing a bike with linear profiles. In other words, no bent tubes. To keep production simple, we challenged ourselves to create a frame that wasn’t reliant on angular tubes. The issue with using straight tubes in a traditional double-triangle design is the extremely narrow limit for tire size and clearance at the seat stays. After many hours of serious brainstorming, trial, and error, we overcame this issue. We created a one-of-a-kind triple-triangle design to accommodate for seat stay clearance. This new design served two purposes:

- Increase tire clearance to our minimum of 32c ± 2 mm with a minimum of 5 ± 1mm sidewall clearance.

- Increase the flexibility of the rear triangle while maintaining elasticity of the frame.

Manufacturing

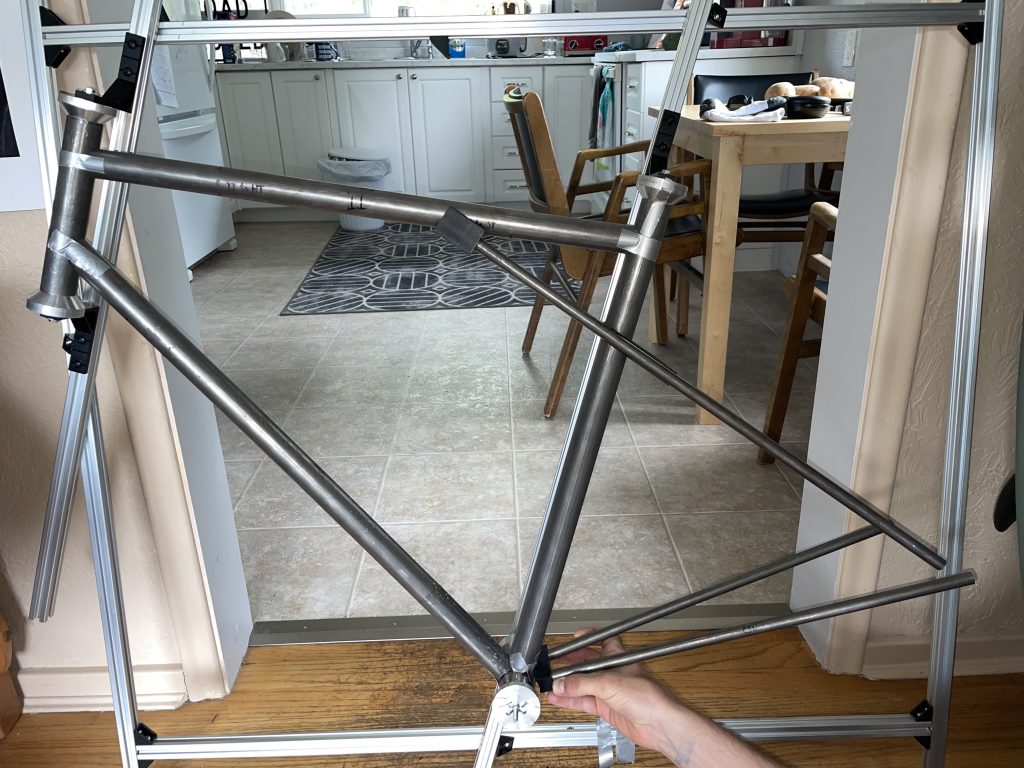

We had our materials, our tools, and our plan. It was time to bring it all together. Our first obstacle was creating a prototype Jig to braze our 4130 steel frame. The best part of learning is running into a brick wall, with another brick wall right behind it. With some help from our partnered clubs and team discussion, we created an adjustable, light, and precise jig. We dedicated a team of minds to the critical task of ensuring an accurate and stable Jig, researching concepts, and thinking through the engineering process. Everything starts in CAD.

After problem-solving a few last-minute hurdles, we created our prototype frame Jig. We turned some aluminum cones to center our tubes, and use some PLA supports ensured our tubes met our desired angles!

Fabrication

After deciding on the tubing and geometry, it was time to weld and assemble! After many hours of searching Facebook Marketplace and visiting second-hand fab shops, we gathered all the tools we needed to melt our bike together. With some help from partnered clubs, the school, and some online resources, we learned the fundamentals and basics of tacking and brazing.

Decorating

We want this bike to outlive all of us! We prepped the bike with some primer for stick and rust, and gave it a beautiful paint bath. Of course with classic UVic colors, blue and gold! The revolutionary Bull Horn bars give an aerodynamic edge, and move the center of mass towards the front of the bike in true gravel fashion!